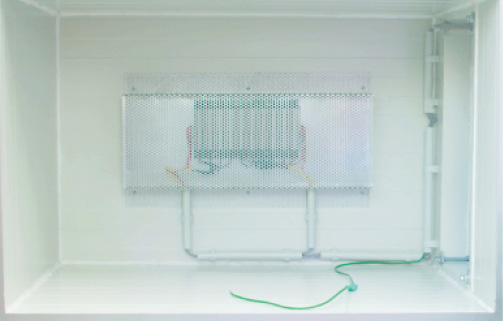

Kraft Curing Systems’ new Match-Cure insulated enclosure heats and cools test cylinders or cubes containing the same mix design as prestressed concrete elements in the production area, replicating their curing conditions. Temperature sensors, wired or wireless, installed in the Match-Cure enclosures and production area, transmit concrete temperatures to the central AutoCure automatic concrete curing control system. It “matches” the temperature in the test cylinders to that of the prestressed elements, up to 160°F. An optional cooling system suiting precast, prestressed production in colder climates reduces temperatures to 40°F.

The quality control measures that match-curing precast, prestressed elements enables include prevention of premature detensioning, which could result in a damaged product, or delayed detensioning which can result in lost production time. Another advantage of the Match-Cure System is the reduction of higher curing costs by preventing unnecessary over-curing and excess energy consumption. Rugged and durable German-engineered design allows placement of Match-Cure ovens in any quality control lab or production area. Kraft Curing Systems’ VaporWare V2 data logger, which measures, records, stores and prints all climatic curing data independently of a computer, provides optimal control.